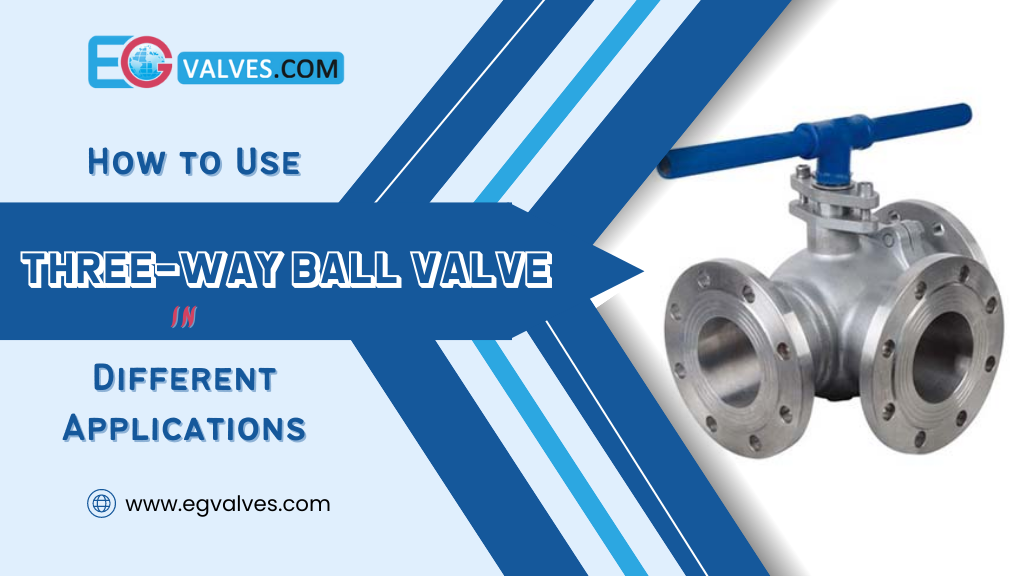

Three-way ball valves are used in products with larger than one supply of media or to bend media in distinct two ways. It differs on the path of the substance movement; the three major ports are consigned as two opening and one inlet or vice versa two inlets and one opening passage. In this article we will discuss three way ball valve uses.

From the name, it is clear that three-way ball valves originate with 3 different ports. It can function mechanically or physically with an actuator i.e. electrically powered or pneumatic actuator. The ball of this valve i.e. three-way ball valve is defined in two different types with “L” and “T” formations. This valve is an explicit type. It is stress-free to use in floating configuration and trunnion configuration with numerous kinds of end valves like sockets, flanged, or threaded.

Three Way ball valves have the ability to execute the below-mentioned roles

- Amended the flow

- Close the flow

- The flow is distributed between two discrete bases

- The flow is combined from two countless bases

- Substitute the movement of flow among two separate targets

- Deflect the flow that is coming from one point to another end

- Division of the flow from one resource to another departing marks

An extremely widespread and prominent multi-port valve is the 3-way ball valve. This multiport valve functions with more than dual tasks. The multiport valve can be a 3-way ball valve, 4-way ball valve, 5-way ball valve, and so on. The three-way ball valve itself evaporates that it has 3 different varieties of ports that pass the flow of substance in gas procedure or liquid procedure. These ports are also consigned as one inlet and two openings or one opening and two inlets according to your necessity. The three-way ball valve is profitable, so it is extremely prominent and best in use. You can effortlessly regulate this valve with two paths in a single body of the valve. With the numerous processes, this 3-way ball valve can offer or control the movement of substance changing on different method needs. One can undertake it by operating the accurate valve selection and control.

The below-stated fundamentals can be accomplished by a 3-way ball valve:

– Entirely switch the movement of flow in any manner.

– Combine two separate substances from different suppliers.

– Development can be conveyed from one medium to another medium.

– Watery flow or gaseous flow from solo inlet can be completed in two unequal points.

– It can finish one opening while consenting to the movement of an element in gas or liquid form and stay in another mode.

The 3-way ball valve is clearly described by a specific, noticeable, internal design division. This foremost internal design division is the current version or the outline port within the valve of the ball.

EG Valves, Three-way ball valves come with flow-repetitive valve balls outline. It comes in an L shape and a T shape. The L shape is described with two flow paths and the T shape is described with 3 flow paths.

Moreover, Three-way ball valves are principally operative and well-designed because they can be positioned in immense methods to streamline the use of gaseous streams and moist streams. For example, they can be used to absorb the flow of oil from one container to another.

Dissimilarities between two-way ball valves and three way ball valves

Two-way ball valves are also known as shut-off valves. It is mainly used to pass the flow of watery substances and gaseous forms of media through closed channels or pipelines. Similarly, Two-way ball valves come with two ports and the ports are connected to the valve that functions properly. In this, the ball works as a single in a row-hole media that let a liquid form of substance or gaseous form of media pass through it.

On the other hand, a three-way ball valve has three interfaces or ports. It switches more dense movement that involves a valve i.e., more than two-way.

In a number of methods, the three-way ball valves are highly constructive and well-operative. Before opting 3-way china ball valve, it is dynamic to know the summary structure and plan design of the valve or any valve manufacturer.

A Three-Way Ball Valve: Functioning and Performance

As earlier explained, three-way ball valves are mainly of two types. One is an L shape and the other one is a T shape. If we talk about the normal ball valve the functionality and performance are slightly different.

L Shaped

The diverter valve is another name for an L-shaped style valve. It simply marks a change in the movement of flow from one port to another port just by rotating the handle to 90 degrees. The foremost plug is unlocked by the close port and the left port. In the counterclockwise track the fourth shot sources the valve to bounce the flow of liquid and gas to the apt opening way.

On the other hand, One more fourth turn in a different route permits a perfect rotation of 180 degrees. It blocks the channel of all sorts of media. A turn of 270 degrees will also complicate the flow of liquid or gas. Though, having a full 360 degrees rotation permits the valve to set back to its preliminary position.

T shape

Mixer valve is another name for T pattern valve. You might think why this valve is known as a mixer valve. It is because the substance of two inlet streams can be combined, shared, or diversified within the valve. On the other end, it drops the valve. In this manner, all three ports can be unconfined and have the ability to achieve any type of function at a time.

The T-shaped ball valve also works as the L-type valve or diverter in a similar way. It could be accomplished with a handle of the fourth turn. To enable the passageway to all three interfaces a T-shaped valve is used in the working to control the flow.

Three Way Ball Valve Uses

As an industrial valve, a 3-way ball valve is highly used for converting valves, by-pass valves, opening valves, closing valves, directional valves, and more with the help of an L-shaped ball-type valve. And, T-shaped ball-type valve is suggested and highly used for merging valves, examining valves, suppression valves, and more.

Let us discuss the features and benefits of a 3-way ball valve

The foremost features and advantages of three-way ball valves are mentioned below:

– It needs less force to rotate the valve.

– It does not require any type of friction to open or close.

– Time-saving and cost-effective.

– It is a self-accusing valve.

The benefits of a three-way ball valve are:

– Accessible to handle and beneficial product.

– Comes in a variety of magnitudes to boost the variety of uses.

– Weight-less which makes it compact in design

– Low level of volume with an easy-to-use structure.

– Low firmness that permits the flow of watery substance through the valve.

– Firmed sealing.

Classification of a three-way ball valve

L-shaped valves

L-Shaped valves, also known as 90-degree balls. It is most widely used to enable the flow from a single common inlet port to one of two independent outlet ports. That is why L- shaped three-way ball valves are also known as diverter valves.

T-shaped valves

T-shaped valve is also referred to as 180-degree balls. To merge, combine or blend two inlet movements of flows into one conformist opening interface. T-shaped valves are suggested for dividing or separating the stream of a liquid. T-pattern valve also plays an important role as L-pattern movement valves usually known as the diverting movement of those actions from one opening port to another port. They may consist of distraction flow, collaborating or separating flow, and straight flow that is predominantly constructed on the allowable range of regulator flow.

Casting

Casting demands a liquid form of metal to create valves. These metals are heated properly to soften and transferred into molds of dissimilar erections and in a variety of sizes. The unsolidified watery substance is fragmented or distant from the pattern formerly it has firmed and solidified. The utmost significant assistance of casting permits the production of valves with complex and dense forms, dimensions, systems, and strategies.

Actuated

A methodological process that switches a valve with the maintenance of a power source is known as an actuator in the valve. This cause of function may be in any form for example: electrically powered, air-filled, or hydraulic.

A three-way ball valve selection

Always keep the below-mentioned points in mind before selecting a three-way ball valve or any China Valve Supplier.

– Identify the fluid substance that is to be used in the structure, this requires selecting the appropriate and equal valve seal.

– To introduce the valve choose the power evaluation of the structure.

– To work on the valve set the appropriate temperature.

– Verify the connection and identify whether the valve is applicable that needs to be attached to the piping or not.

– The substantial needs to be friendly with the active course and suitable for the course heating level and power.

– Create the switch device of the valve to attain the function in the current system.

How a two-way ball valve is not the same as a three-way ball valve (variance among 2-way ball valve and 3-way ball valve)

The two-way ball valve is mainly utilized for shut-down services. This valve has two openings mainly on two equal ends that are linked to the pipe ways. This valve has one straight hole opening by which the fluid or vapor passes.

Furthermore, 3-way ball valves are used for 3 ports. This valve is compatible with more complex control procedures that the two-way variation cannot achieve.