Butterfly valves China have become widely used in various industries due to their simple design, cost-effectiveness, and minimal pressure loss. Nevertheless, selecting the apt butterfly valve material is critical to ensure optimal performance and durability. This comprehensive manual delves into the array of butterfly valve materials obtainable. And aids in establishing the most fitting one for your specific usage.

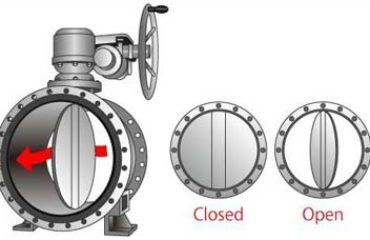

The versatile butterfly valve finds wide-ranging applications in industries such as HVAC, chemical, food and beverage, and pharmaceuticals. Where it regulates the flow of gases and liquids. Its design features a circular disc that revolves around an axis perpendicular to the direction of flow, connected to a stem that can be actuated by a handle or an electric/pneumatic actuator. This enables its use in various applications, adding to its flexibility as a valve solution.

The choice of material for butterfly valves depends on several factors, including the type of fluid, pressure, temperature, and corrosiveness of the medium. This guide will expound upon the prevalent materials for butterfly valve China, covering their characteristics, benefits, and drawbacks.

Butterfly Valve Applications that work best

Butterfly valves are known for their versatility and are capable of adapting to a wide range of applications due to their distinct operating principles. They are also highly durable, require low maintenance, and provide a tight seal. Some of the common applications where butterfly valves are used include:

Food Processing:

In the food processing industry, it is mandatory to use certified food-grade seats, with a preference for white seats. Although standard resilient-seated valves may not be approved by 3A, there are several options available in the market that maintain hygienic connections both inside and outside. Valve body materials range from Epoxy-coated iron, Nylon 11-coated iron, Bronze, 304SS, to 316SS, offering a variety of choices.

Refineries:

Refineries commonly employ butterfly valves, with a preference for high-performance steel-bodied valves or triple-offset designs that are “fire safe” and bubble-tight. The resilient-seated variation usually finds application in scenarios that involve water.

Valve for shutoff:

Butterfly valves are an excellent choice for general shutoff applications above 1.5″ -148″ due to their simple design. They take up less space and weight compared to other types of valves, making them a preferred choice. Butterfly valves provide a tighter seal when compared to the gate or globe valves and are typically bubble-tight, which means they obstruct any fluid passage through the pipeline upon closure.

Ship Building:

Butterfly valves are a popular choice in shipbuilding due to their high durability in saltwater. Materials approved by the ABS are typically chosen for this application. These valves are effective in creating a watertight shutoff in the piping system of a ship, blocking any flow within the pipe. Their compact size makes them ideal for use in confined spaces onboard a ship. Butterfly valves are suitable for diverse applications, including ballast systems, jack-up rigs, and ship sides. In many cases, fire-safe-approved valves are a necessity. The valves’ versatility is further enhanced by their automation and pneumatic functions, including closed-loop pneumatic underwater, electric, and hydraulic options.

Common Materials for Butterfly Valve China

There are several materials available for butterfly valves, including:

Cast Iron

Cast iron is one of the most common materials used for butterfly valves due to its low cost and excellent corrosion resistance. It is suitable for use in water, steam, and gas applications and can withstand temperatures up to 400°F. However, it has poor performance in highly corrosive environments, and its strength decreases at high temperatures.

Carbon Steel

Carbon steel is a popular choice for butterfly valves in high-pressure and high-temperature applications due to its high strength and durability. It is suitable for use in oil, gas, and chemical industries and can withstand temperatures up to 800°F. However, it is susceptible to corrosion and may require coatings or linings to protect against rust and erosion.

Stainless Steel

Stainless steel is a corrosion-resistant material that is well-suited for use in harsh environments and high-temperature applications. It is available in various grades, each with different properties, such as strength, corrosion resistance, and heat resistance. Stainless steel butterfly valves are widely used in industries such as chemical, pharmaceutical, and food and beverage, where hygiene and resistance to corrosion are crucial factors.

Duplex Stainless Steel

Duplex stainless steel is a corrosion-resistant material that offers excellent strength and toughness. It is suitable for use in aggressive environments, such as seawater, chemicals, and acids. Duplex stainless steel butterfly valves are commonly used in offshore and marine industries.

Nickel Alloys

This Nickel alloys, such as Monel, Inconel, and Hastelloy, are highly corrosion-resistant and suitable for use in extreme environments, such as high-temperature and highly acidic or alkaline applications. Nickel alloy butterfly valves are frequently used in industries. Such as chemical processing, petrochemical, oil and gas, and other applications that involve corrosive fluids or gases. The nickel alloy material provides excellent corrosion resistance and high-temperature strength, making it an ideal choice for demanding environments.

Choosing the Right Material for Butterfly Valve China

When choosing the right butterfly valve material for your application, several factors must be considered, including the type of fluid being handled, pressure and temperature requirements, and environmental conditions. To help you choose the right butterfly valve material, here are some tips:

Consider the fluid being handled: The type of fluid being handled is a crucial factor in selecting the right butterfly valve material. For example, if the fluid is corrosive, a stainless steel butterfly valve may be the best option, while if the fluid is abrasive, a cast iron butterfly valve may be the best choice.

Consider the pressure and temperature requirements: The pressure and temperature requirements of the application are critical in selecting the right butterfly valve material. Cast iron butterfly valves are a good choice for applications that require high pressure and high-temperature resistance due to their durability and strength. On the other hand, PVC butterfly valves are commonly used in low pressure applications because of their affordability and resistance to corrosion.

Consider the environmental conditions: Consider the environmental conditions such as humidity, temperature, and chemical exposure that can affect the performance and durability of the butterfly valve. For example, in corrosive environments, a stainless steel butterfly valve may be the best choice, while in harsh environments, a cast iron butterfly valve may be more suitable.

Advantages and Limitations of Butterfly Valve Materials

Each butterfly valve material has its advantages and limitations, depending on the application requirements. Here are some of the pros and cons of common butterfly valve materials:

Cast Iron:

Advantages:

- Low cost: Cast iron is a cost-effective material, making it a popular choice for applications where cost is a significant consideration.

- Good corrosion resistance in water and steam applications: Cast iron is resistant to corrosion in water and steam applications, making it suitable for use in water and wastewater treatment, HVAC, and other similar industries.

- Suitable for low-pressure applications: Cast iron butterfly valves are suitable for use in applications with low to medium pressure, typically up to 150 PSI.

Limitations:

- Poor performance in highly corrosive environments: Cast iron butterfly valves are not suitable for use in highly corrosive environments. They are susceptible to corrosion and erosion in aggressive environments.

- Weakens at high temperatures: Cast iron has a maximum temperature rating of around 400°F, above which it can become brittle and lose strength.

Carbon Steel:

Advantages:

- High strength and durability: Carbon steel is a sturdy and robust material that is well-suited for use in applications with high temperatures and pressures.

- Suitable for high-pressure and high-temperature applications: Carbon steel butterfly valves can withstand temperatures up to 800°F and pressures up to 600 PSI, making them suitable for use in oil and gas, chemical, and power generation industries.

- Resistant to mechanical wear and tear: Carbon steel is resistant to mechanical wear and tear. Which means it can handle high-stress situations without degrading quickly.

Limitations:

- Susceptible to corrosion and rust: Carbon steel butterfly valves are susceptible to corrosion and rust, especially in harsh environments. They may require coatings or linings to protect against corrosion and extend their lifespan.

- May require coatings or linings for protection: Carbon steel butterfly valves may require specialized coatings or linings to protect against corrosion and extend their lifespan in corrosive environments.

Stainless Steel:

Advantages:

- Corrosion-resistant: Stainless steel is highly resistant to corrosion and rust, making it suitable for use in harsh environments and corrosive applications.

- Suitable for harsh environments and high-temperature applications: Stainless steel butterfly valves can withstand temperatures up to 1000°F and pressures up to 1500 PSI, making them suitable for use in chemical, pharmaceutical, and food and beverage industries.

- Available in various grades with different properties: Stainless steel is available in various grades, each with different properties such as strength, corrosion resistance, and heat resistance. This allows for more customization based on the specific application requirements.

Limitations:

- More expensive than other materials: Stainless steel is more expensive than other butterfly valve materials, making it a less popular choice for applications where cost is a significant consideration.

- May require specialized welding techniques: The process of welding stainless steel requires specialized techniques and equipment. Which can result in an increase in the overall cost of the valve.

Duplex Stainless Steel:

Advantages:

- Corrosion-resistant: Duplex stainless steel is highly resistant to corrosion and pitting, making it ideal for use in aggressive environments such as seawater, chemicals, and acids.

- Excellent strength and toughness: Duplex stainless steel has high strength and toughness, making it suitable for use in demanding applications.

- Can withstand high temperatures and pressures: Duplex stainless steel butterfly valves can withstand temperatures up to 600°F and pressures up to 3000 PSI, making them suitable for use in offshore and marine industries.

Limitations:

- More expensive than other materials: Duplex stainless steel is more expensive than other butterfly valve materials, making it a less popular choice for applications. Where cost is a significant consideration.

- Requires specialized welding techniques: Welding duplex stainless steel requires specialized techniques and equipment. Which can add to the overall cost of the valve.

Nickel Alloys

Advantages:

- Highly corrosion-resistant: Nickel alloys, such as Monel, Inconel, and Hastelloy, are highly corrosion-resistant and suitable for use in extreme environments. Such as high-temperature and highly acidic or alkaline applications.

- Suitable for high-temperature applications: Nickel alloys can handle high temperatures, making them suitable for use in high-temperature applications.

- Provides excellent resistance to mechanical wear and tear: Nickel alloys are known for their excellent resistance to mechanical wear and tear, making them ideal for applications that require high levels of durability and reliability.

Limitations:

- More expensive than other materials: Nickel alloys are generally more expensive than other butterfly valve materials.

- May require specialized welding techniques: Nickel alloys require specialized welding techniques that can increase the cost of installation and maintenance.

Here are some frequently asked questions related to materials for butterfly valve China:

1. What is the most commonly used butterfly valve material?

Cast iron is the most commonly used butterfly valve material due to its low cost and excellent corrosion resistance. It is suitable for use in water, steam, and gas applications and can withstand temperatures up to 400°F.

2. What is the best butterfly valve material for corrosive environments?

Stainless steel is the best butterfly valve material for corrosive environments. It is a corrosion-resistant material that is suitable for use in harsh environments and high temperature applications.

3. What is the best butterfly valve material for high pressure and high temperature applications?

Carbon steel is the best butterfly valve material for high pressure and high temperature applications. It is a strong and durable material that can withstand temperatures up to 800°F and pressures up to 600 PSI.

4. What is the difference between cast iron and carbon steel butterfly valves?

Cast iron butterfly valves are suitable for low-pressure applications, typically up to 150 PSI, and have good corrosion resistance in water and steam applications. Carbon steel butterfly valves are ideal for use in high pressure and high temperature applications. And are resistant to mechanical wear and tear.

5. What is duplex stainless steel, and where is it commonly used?

Duplex stainless steel is a corrosion resistant material that offers excellent strength and toughness. It is suitable for use in aggressive environments, such as seawater, chemicals, and acids. So, it is commonly used in offshore and marine industries.

6. What are nickel alloy butterfly valves, and where are they commonly used?

Nickel alloy butterfly valves, such as Monel, Inconel, and Hastelloy, are highly corrosion resistant. And suitable for use in extreme environments. Such as high temperatures and highly acidic or alkaline applications. So, they are commonly used in the chemical, petrochemical, and oil and gas industries.

Conclusion

In conclusion, by choosing the right butterfly valve material is crucial for ensuring optimal performance and longevity in various industrial applications. Cast iron, carbon steel, stainless steel, duplex stainless steel, and nickel alloys are the most common materials used for butterfly valves. Even so, each with its own advantages and limitations. When selecting the right material, factors such as the type of fluid, pressure and temperature requirements, and environmental conditions must be considered. By understanding the properties and limitations of each material. You can choose the best material for butterfly valve China ensuring efficient and reliable flow control.