In accordance with some particular specifications and functions, industrial valves can be classified into many different kinds. A prime member of the valve family that is making big contributions to many industrial processes is the ball valve or ball valve mechanism. Just like other kinds of valves, the ball valve is designed to control the flow. What distinguishes it from others is the spherical disc. It is designed in such a manner to regulate the high level of control and ability to be disassembled in case any problem may occur.

To completely shut off the fluid drift utilizations, ball valves offer the best. Right here, the valve seems constant on the principle line to offer drift. Also, ball valves are compact and easy to keep the tool. The user now does not want to fear approximately dangerous external factors. Such valves are pretty resistant over the years as they’re made up from corrosion –repellent substances. Because of the simple installation method, ball valves make certain sturdiness and secure functioning by making sure of an exquisite seal.

To meet some special industrial requirements, there is a further classification into several types. From the perspective of different body kinds, ball valves can be categorized into a single body, three-piece body, split body, top entry, and welded ones. This sort of classification is made depending on the number of pieces of the valve. Although they are known by different names and design characteristics, the functionality of the ball valves is similar.

Taking into consideration the bore of the ball mechanism itself, there are different styles such as full port, reduced port, trunnion, V port, and cavity filler ball valve. When it comes to distinguishing between manual and automatic ones, the former can be closed swiftly. While others are equipped with an actuator, are motor operated, and can be handled pneumatically. Such kinds of valves are usually equipped with a positioner. This makes it convenient to transform the control signal into the actuator position and valve opening consequently.

For instance, the multi-port ball valves are commercially available that usually come in 4 or more ways. From forward to reverse motion, the driving air-powered motors make the functionality possible with a single lever four-way ball valve. Whereas, the one-piece ball valves are reduced bores that are cost-effective. Two-piece ones are somewhat reduced as they can either be thrown away or repairable.

Applications and Challenges of Ball Valves

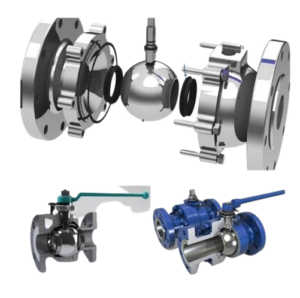

To gain clear insights into the ball valve mechanism and its working principle, it is significant to know the crucial ball valve parts and different functional kinds. The essential components include the valve stem that connects to the ball and can be either operated electrically or pneumatically. The mechanical device gets the required support from the ball valve seat and the O-rings that are around the valve stem.

The bore through the ball can either shut to restrict media flow or can be opened to pass media. The components that affect the functionality of the valves include the housing assembly, valve circuit function, design of the ball, and all other functionality kinds that may affect it.

Ball valve mechanism specialized to regulate fluids under high temperature and high pressure. It is common that such mechanisms hold certain benefits. This has been proven by industrial usage, that ball valves are convenient and economical to install and hold a longer service life in comparison to others.

Referring to the disassembly, it is moderately easy with some easy equipment. This system requires an approach to conducting in line with the instructions. And the specified equipment can be easily accessed. They can be an adjustable wrench set, safety glasses, safety gloves, and safety glasses.

Reliable sealability

Ball valves come with many useful characteristics and one such is reliable sealability. While used in long pipelines, ball valves can be checked at regular intervals and can easily pass through high mountains, deserts, grassland, earthquake regions, and other places too. Sealability is a crucial aspect that may lead to leakage and even serious accidents. In order to avoid such things, the china ball valve must ensure good sealability, more specifically for urgent grease injection. In the current industrial scenario, the sealing elements that are quite in use include flexible materials such as PTFE-Polytetrafluoroethylene. Such elements when incorporated with metallic and non-metallic materials form soft sealing. To match the effectiveness of soft sealing needs low matching precision and rough surfacing.

Long operation time

Once in operation, the ball valve mechanism can continue to work for several years without any interruptions. The more durable the valve is, the better it proves for the industries. In order to enhance the service time, the valve seat is highly significant. The entire process depends on the use time of the valve. The self-lubrication feature of PTFE decreases the friction between the sealing element and the ball. Besides, the improvement in machining capabilities lowers the hard surface of the ball, increasing the lifespan.

Resistant to corrosion

In the pipeline ball valve system, it is crucial to choose a resistance-proof ball valve. This is due to the fact that natural gas contains Hydrogen Sulfide that may erode the valve and damage the device. Irrespective of whether it is reduced or full port, its flow factor with the flow resistance is less, more specifically in the full-port type. The passage diameter of the port ball valve is the same as the pipe diameter. It makes the partial resistance identical to the friction resistance of the pipe. Thus, the full-port ball valve ensures the minimum flow resistance in comparison to the other types.

The simple layout of the ball valves is at the back of the versatility of the product. This is why these valves can easily resist excessive strain, without any chance to worry. Furthermore, they are easily adaptable to guided operations. Also, the easy shape without difficulty fits the sort of materials whilst permitting the same to be used for corrosive liquids.

Automatic functionality

To control the process from a long distance immediately, the ball valves can be regulated automatically. The design and structure of the ball valve are light in weight and tight in structure, the ball valve is easy to install and use. Its 90-degree guide handle is easy and short to open and close. In a few cases, it simplest takes as low as zero to complete the action. So it is a prime aspect of the automation system.

Engineers develop valves for different applications and match the overall performance of the valve’s elements with the needed flow, temperature, and other aspects. Carefully designed excessive pressure and high-temperature ball valves can preserve temperatures as high as 400°f and multiply pressures up to thousands of psi.

Design of the Ball

The length of the port and the position wherein the ball is kept in the valve frame are the greatest elements of the ball layout. Port size is defined as the hollow diameter. Which exists in a few common sizes such as standard, reduced, and full. And, when it comes to materials that are required to form the ball layout include chrome steel, copper, bronze, brass, and forged iron.

Complete port design

In the full port design, the port size is kept approximately equal to the pipeline’s inner diameter. Such designs best suit the applications that warrant minimal resistance to the float of fluids.

In comparison to the full port designs, the diameter of standard port ball valves is small and results in improved resistance to fluid going with the flow. They may be used as alternatives to gate valves in several fluid applications.

The diameter of a reduced port ball valve is about the same as more than 50% of the valve’s internal diameter. This ball valve layout best suits the small, end-loaded valves that require small-diameter balls. A ball valve’s waft-managed sphere element may be assembled to the ball housing via two methods: the trunnion-mounted ball layout and the floating-ball design.

In the trunnion design, the ball gets supported by two trunnions and the small-shaft extension at the top of the ball and where the bottom ends. Such trunnions are attached to bearings which are then attached to the body of the valve. In the case of high-pressure applications, the ball valve is placed by trunnions. A slot in the top short-shaft extension easily accepts the flow control shaft. This kind of support method is primarily effective in the kind of ball valves that come with a split body style and design.

However, in the case of the floating ball design, two seat rings are used to support the ball. In such a design, the flow control shaft is attached to the ball at a slotted right angle. Getting this kind of support makes the ball valve move or float in the direction of the seat ring. During the closing of the ball valve, it is the pressure of the fluid that lets the ball move the seat ring at the bottom. In general conditions, the floating ball design works best for low to medium-pressure usages. However, for industrial applications in high-pressure circumstances, the trunnion design is the better choice.

Valve Handle

The ball valve handle forms a connection with the stem of the valve that is designed to turn the valve from the open or closed position. If the installation is made adequately, the ball valve can be made open in the parallel position of the valve. It gets closed when the ball valve handle gets 90 degrees to the pipe. Here, the direction and angle of the handle have a significant role in knowing whether the valve is in a closed position or an open one. Additionally, the ball valve handle types include handwheels or lockable handles. For a greater ball valve that requires additional force for opening or closing, the handle extension is needed. In case of any breakage in the handle, or it is misplaced, the conversion of an automatic ball valve to the manual one is possible.

Seats

Smooth seats are made from resilient substances like PEEK, TFE, and PFA. Through the right layout, soft seals can be utilized in leak-tight flow regulation applications. But, the performance of soft seat rings is restrained using their provider temperatures. Soft seat rings can be manufactured in jam and bendy seat designs. In jam seat design, as the name indicates, the seat ring is compressed through the drift manipulation ball at some stage in assembly. This layout complements sealing efficiency; however, the design isn’t perfect for huge temperature and pressure fluctuations. The bendy seat layout overcomes this difficulty by encapsulating the seat that bends when compressed in the course of assembly.

It is highly significant to choose the right sealing material for the purpose to ensure reliable sealing. The quite popular and preferred choices include metal material and special high polymers that can be further classified into common and special ones.

And, the metal seats are manufactured from base metals that are coated with Stellite and Tungsten Carbide. Though metal seats easily withstand high pressure and temperature conditions, metal seats do not ensure fully tight leaks like soft seated rings. Also, these are not as strong as the soft seats, springs are used in the production process in order to maintain contact pressure. In the trunnion designs, the upper and the lower seats are supported with two different springs. While in the case of the floating ball valve mechanism, only one spring is used to maintain pressure in contact.

What enhances the efficiency of sealing in metal seat rings is the installation process of a backup seal. Generally, graphite seat rings and flexible metal rings best suit flow control and high-temperature conditions. Also, the metallic seats best work for specific applications that use abrasive solids in the fluid. For instance, the top-entry, split body, and three-piece come under metal seats.

Get in touch with EG Valves Manufacturing Co., Ltd

EG Valves Manufacturing Co., Ltd is a renowned manufacturer and provider of industrial valves. Being in the industry for over twenty years, the Company ensures to offer quality products to meet specific necessities. Visit us today at EG Valves to learn more about our products and services.