Butterfly valves are the popular kind of quarter-turn valves that are designed to control the flow of liquid. The appearance of the butterfly valves is similar to a thin metal disc; however, the mechanism used in the system restricts or passes the flow of gases, fluidized solids, and liquids in pipes. Typically, the device manages the flow of such substances in a way by closing, opening, or partially obstructing different passageways. This guide on China Butterfly Valve will give you detailed information.

China butterfly valves can be used in two ways; either driven by pressure like in steam engines or can be utilized in a controlled manner, likewise in the engine cycle control.

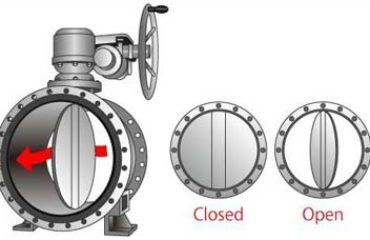

The entire mechanism of the guide on China butterfly valves is controlled by a rotating disc that directs the circulation of liquid in a specific system. This disc can be rotated 90 degrees, and for this reason, it is named a quarter-turn valve. The prime components together work to make the unit perform accurately, such as the piston, cylinder, electric motor, and pneumatic actuator.

Butterfly valves are of different kinds. The only is the excessive-overall performance China butterfly valve, that’s commonly double eccentric in design, with pressure for up to 725 PSI. Every other type is the resilient seated butterfly valve, which has a flexible rubber seat, with pressure for up to 232 psi. And, sooner or later, the closing kind would be the pericentric butterfly valve that is usually designed with metal seating, with the valve running strain for up to 1450 psi.

The best part about these valves is the affordability and ease to which they can operate well. As a matter of fact, these valves are quite inexpensive when compared to the other kinds of valves.

What are China Butterfly Valves used for?

For throttling specifications, China butterfly valves are preferred to utilize for many kinds of industries. Such valves can be used to process huge capacities. In the piping systems, such devices can be used to pass liquid flow, however, are not suitable to manage thick liquids because of their fragile nature.

More commonly, Butterfly valves are used across a lot of industries including wastewater treatment, lubrication, Agricultural needs, Air conditioning systems, Petroleum Industries, Sprinkler systems, Vacuum service, High-temperature areas, and HVAC.

Sanitary butterfly faucets also are becoming increasingly popular for industrial and general purposes. This is due to the strong need to maintain hygiene in piping structures, specifically for the food, pharmaceutical, chemical, and beverage industries. And, there is no better way in comparison to acquiring a butterfly valve that isn’t only smooth to clean but additionally designed for hygiene.

There are a wide number of applications that have made the China butterfly valves in huge demand. More common are liquid, steam, and air. For such specific units and devices, these kinds of valves are used to manage materials that are being displaced by the valve disc. Here, the need is to make a wise selection according to the units used in an abrasive or semi-abrasive part.

What to consider before making your purchase of China Butterfly Valves?

When choosing to use China Butterfly valves, the need is to consider the classification of these units. Depending on the application, you can make a selection among the materials of the disc body and seat.

For the body of the valve, the structure is designed in a manner to ensures optimal functionality. It can be created in certain materials, out of which more common choices are stainless steel, iron cast iron, carbon steel, and others. Such units can be found in regular styles of industrial valve, where the installation is performed between flanges of the pipes. The associated benefit is the ease of installation and replacement. Whereas, the other types have tapped holes that allow you to bolt them to a flange. The material is sealed with the closing of the valve.

When it comes to the seat of the butterfly valve, it can either be metallic or resilient seated type. The inner part lines up with an elastomer seat which is usually formed with materials like white neoprene, natural rubber, carbon, and EPDM. The selection of the material directly relies on the pressures, and temperatures of the application. Often, the seat of the low-quality valves cannot be removed or repaired. However, this is not the case with the high-quality or precision units that can be replaced or repaired as they come with removable seats.

The valve disc performs its unique functionality to pass the flow in the conveying line. When it comes to choosing material for it, it can be according to the usage. More commonly, the materials used for the disc part include nickel-plated, coated with epoxy, ductile iron, aluminum, stainless steel, and ductile. Another vital component of the China butterfly valve is the stem which makes a connection with the actuator and adjusts accordingly with the material flow. Depending on the valve size and its usage, the stem of the butterfly valve can be made according to the number of pieces required. Usually, the kind of materials used in the stem includes carbon, ductile and stainless steel.

Furthermore, it is significant to consider the environment in which you will use the valve before making any kind of purchase. Although there are certain kinds of options available, it is essential that you find an industrial valve that fulfills your specific needs. For instance, working with high-temperature and high-pressure piping systems are the two vital considerations.

Material

The construction material of Butterfly valves is behind the sturdiness and capability. Take it as an example, strong metals are usually preferred for units that are designed to manage the waft of thick liquids under high pressure. Different styles of devices are designed for lighter use which is why they are made from smooth metals, inclusive of % plastic, aluminum, and mild alloy, just to name some.

Applications

It is vital to head for a wall primarily based on a specific utility. The units that are light in weight are considered a perfect choice for fuel line handling or small water traces. For example, pools and aquariums rely on these units. On the contrary heavy applications likewise, oil delivery systems, and gas pipelines need valve installation valves with a quick check on the system. These units are regarded for their reliability and high performance. Consequently, it’s vital that you pass for the proper valve based on the type of utility. This may reduce the likelihood of mechanical failure.

Precision level

Another critical component that you could need to recollect while deciding on one is the diploma of precision. These units are created for an amount of leakage in any particular application. This could be different whilst the valve is open or closed. Besides considering this aspect, the precision level is another factor that decides reliability.

Managing options

Other than the basic installation process, the way to manage the unit is another pivotal element that should be taken into consideration when choosing a valve. In some units, you can find a take care of or a lever that you may open or close manually. Generally, the control flow is straightforward to apply, so you can manipulate the device based totally on your needs. Some of those devices are automated. Advanced units make use of a powered motor. The motor can rotate the shaft of the unit or the liver with the usage of a unique actuator arm. Therefore, you have whole control over the device from a far-flung location.

Valve capability

The capability of the unit is the most critical factor when making this purchase. This includes specs that inform you how plenty of fabric can drift thru the valve in a sure length and what kind of pressure the unit can tolerate. For high pressure, better-end gadgets are required which can meet the required desires. Consequently, you may need to check the specifications to make certain that the device can manage its weight.

To enhance the overall performance of a valve it’s miles critical that the right valve is selected for the service required. There are some one-of-a-kind conditions and variables to not forget to select an appropriate valve for a selected application. These variables will largely be dictated using service situations and necessary substances of creation.

When thinking about service situations step one is identifying what sort of medium will be treated. Distinct valve designs are more appropriate for liquid whilst others are preferred for fuel. If it’s far from a liquid, it’s miles critical to determine whether or not or not it’s going to comprise any stable particulate depend. It is also critical to be aware of whether or not the media will stay liquid throughout the go-with-the-flow or whether it’s going to vaporize and come to be a fuel along the way.

Any other variable to remember is what the pressure and temperature could be at some point in managing the system. This will now not handiest dictate the perfect type about but also what cloth the valve needs to be made from. For instance, at extremely high temperatures it may be necessary to apply ceramics or refractory metals. At very low temperatures bronze or chrome steel can be required. The widest choice of construction materials falls within the intermediate variety.

For the designing part, the China butterfly valves are categorized into components: Lug style and wafer style. The most typically used design choice is the wafer style which is pretty less expensive as nicely. They have been designed in the sort of manner that prevents backflow for the one-glide direction systems. A tightly becoming seal is used, like a gasket on both aspects of the industrial valve to decorate its functionality. On the opposite facet, lug butterfly valves feature threaded inserts which can be hooked up using a hard and fast bolt. The installation is carried out in one of these ways so that it does not affect the alternative machine while being disconnected. If used in a useless-stop piping machine, it features a discounted strain degree.

Thermoplastic type

Such units are available in lug and wafer styles. Every one of these kinds has a one-of-a-kind installation procedure. The lug style is utilized in a device in which a low-pressure rating is needed maximum of the time.

Triple offset

Those devices are characteristic of high performance and can be located in refineries. Other than this, they can be determined in offshore structures, particularly in environments where conditions are intense. A few triple offsets feature the metal-on-steel seat and disc closure. The splendor of this device is that it is fire-resistant.

Double offset

These devices are designed to withstand temperatures of as much as 1200 ranges Fahrenheit. Those valves feature a double offset disc. Besides, it has a stem that permits the disc to move again into position while closed.

Inflatable type

This product uses an inflatable seat to create a seal around the disc. As quickly as the disk hits the closed point, the machine pumps up the bladder pneumatically. In those varieties of units, the seal is created as soon as the disc is closed, that’s why much less electricity is required to make the disc close.

These valves can seal the pipes, thus providing protection against impairment as well as being an energy-saving option. For instance, in the colder months, China butterfly valves allow liquid in the pipes to pass without restrictions. No matter the enduring corrosion and oil, it would pass through tubes and pipes.

In conclusion!

When it comes to valve applications, weight and space offer a lot of benefits in comparison to the other valves. The right selection can be made according to the working conditions likewise manual, electric, or pneumatic valves. Based on the working scenario, usage, and advantages these units offer, it is easy to get a clear idea of the China butterfly valve manufacturer and a selection can be made. To learn more about the China Butterfly valves, visit EG Valves!