Industrial valves have made big contributions to the expansion of modern industry. In fact, the development in the valve industry has brought huge benefits to certain aspects of the industry. The many different types available in the industrial valves are manufactured to regulate the flow of fluid. The regulated fluid can be gas, solid, liquid, or combinations.

The precise function of the valves relies on the actuating device or the fluid movement which is behind rotating, sliding, turning of the parts to open or close the flow passage area.

The Advancement in the China Valve Industry

The demand for industrial valves is rising exponentially and has also made certain changes in the valve automation industry. Now industries are focusing to reap all the benefits offered by the valve industry.

Technological advancements have influenced valve automation by breaking down it into certain categories with all unique services. These cover fluid power actuators, limit switches, positioners, electric actuators, network capabilities, etc. Depending on the industry and usage, the specific application and valve type can be selected.

With all the new features and advancements added, the operator will have complete hold to make quick and efficient variations in terms of certain parameters including open time, close time, and flow characteristics. It’s simple structural design, as well as device portability, proves extremely useful to meet different application needs.

Most of the mechanical valves find their application in the plumbing and piping industry in some of the prime industries including oil, gas, mining, and water/sewage industries. Also in the household and commercial industries, hot and cold taps are commonly used valve types. There are simple valves as well that are hand-operated and can be controlled manually by turning the handle or wheel. In comparison, the complex valves require an external force to function. These are automated types and rely on the actuator that stroked the valve considering the set-up and input. Such an operative set-up makes the valve be positioned precisely which in turn leads to adequately controlling specific requirements.

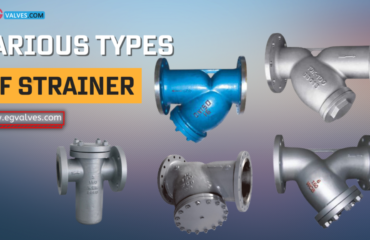

From isolation to regulating flow in certain industrial applications, there are many different valve types that may perform similar functions yet are different.

To understand the functionality of valve types, let’s take an in-depth look at the most commonly used kinds of valves: Butterfly, Ball, Gate, Globe and Check valves.

The Industrial Butterfly Valves

A significant member of the quarter-turn family, the butterfly valves are widely used in certain applications related to water supply and wastewater management. For the enormous diameter pipes, butterfly pipes are quite a popular choice.

The butterfly comprises an actuator, stem; circular disc, seat, and body, and each of these components is made of different materials. In order to withstand extreme temperatures, metal is mainly used to construct seats for better functionality. The advances in technology have made manufacturers come up with an upgraded version of the butterfly valves. For instance, the most basic model of the butterfly valves is usually used to manage different degrees of temperatures and pressure. However, the recently available models are larger and are designed to handle more pressure. Every aspect of the butterfly valve signifies enhancement to functionality and effectiveness.

- Easy and quick to function

- Ideal to use for large flow and low-pressure applications

- Works well for slurries or suspended solids

The Industrial Ball Valves

The working mechanism and the structural part of the ball valves are almost similar to that of the butterfly valves. Also a member of the quarter-turn valve, ball valves are one of the simplest models to operate for flow and pressure control. These are basically rotational motion valves that are used to start or regulate flow. It has a ball-shaped disk with a hole that gets in line with the flow direction. However, when shut, the ball rotates perpendicularly to the direction of the flow.

With its leak-proof feature and quickness to function, the ball valves are quite popular in the manufacturing, oil, and chemical storage sectors. Also for residential use, ball valves are used extensively due to their versatility and range of supporting features.

Due to its easy operation and specifications, the capabilities of ball valves have crossed the higher level of achievement and led the gate and throttle valve in certain applications.

- Compact, and cost-efficient

- Low maintenance required

- Quick 90-degree turn On/Off

- Low torque

- Easy to operate

- No lubrication

- Tight sealing

Check Valve

Unlike other valve types, the working mechanism of the check valves varies in a manner that passes the flow across the pipeline system in a single direction. To get activated, these valves depend on the amount and fluid pressure of the system environment.

The most basic function performed by the check valves in backflow prevention applications, flood prevention systems, and wastewater systems. The excess flow check valve is a disc kind valve that is held open with the aid of a spring however closed via excess glide from the flow downstream. These valves are broadly used in loading and unloading operations.

Check valves respond to the pressure differences, where the fluid pressure is greater than the pressure. This upstream water brings high differential pressure that allows the streams to pass through, while the backflow decreases the differential pressure across the body. Due to their ability to prevent backflow, these valves are also called Non-Return Valves.

This reverse-flow application has made this kind of valve a wonderful choice to be used in pumps and compressors. They are also applied in procedure structures that have varying pressures, which should be kept separate. They do not need a door’s electricity to deliver to operate considering that they use the stress drop created through the media flow.

- Self-automated

- Prevents backflow

- Backup System

- Horizontally/vertically usage

- Easily maintains pressure

Globe Valves

A globe valve comprises two halves, isolated by opening with a plug or disc that can be screwed in, or unscrewed to open and close. Usually, it is used to on, off, or regulate flow in a system.

The globe valves are designed with a stem that shows movements up and all the way down to adjust the waft within the valve, carries a disc (ball, composition, or plug), and seat which is typically screwed into the valve body. Being spherical with two halves, it is separated by a baffle that is parallel to the pipe. If compared to other kinds of valves, globe valves hold a string shutting mechanism with less receptive to leakage and faults.

- Little/no leakage than other valves

- Good shutoff capabilities

- Easy to maintain

- Throttling and regulating the flow

- No resistance to flow

- Best suits the difficult environments

- Alternative to the stop-check valve with the disc not attached

- Easily operated

Globe valves are used in many applications where constant fluid flow is not necessarily needed. For Instance in the feedwater or chemical feed systems, cooling water systems, boiler, and turbine lube oil systems.

Top Industries That Use The Common China Valves:

Power Industry

For the power plants that generate electric power using fossil fuel and turbines, gate valves are commonly used. For On/Off applications, the Y-pattern globe valves are used.

With the arrival of smart technology in the power industry, high-performing ball valves are also gaining huge popularity. For the ancillary pipelines in power plants, a variety of butterfly, check, ball, and globe valves are used.

Water Distribution Systems

Also, the gate valve is used in the distribution systems with the necessary wedge. The up and down of the wedge decide the in and out of the required flow. Another popular valve type in the water distribution systems is the check valve that passes the forward flow and prevents the reverse flow effectively. Usually, this kind of valve does not prefer to be used vertically in the pipelines.

Wastewater Systems

Under normal pressure and temperature conditions, the required pressure existed in any water line to keep the water flowing in the desired direction. However, the pressure drop or other plumbing issues may affect the flow and could lead to backflow in the mainline.

Here, the use of check valves prevents the contaminated water from coming into contact with the clean supply. Whether it’s the main breaks or frozen pipes, the valves block and reverse the direction of water and make it where it should be. With many kinds of valves available, double check valves, and air gap valves are the preferred choices.

Oil and Gas Production

Oil and gas production facilities require heavy-duty valves such as well-designed gate valves and globe valves to regulate the flow. For these facilities, the valve is required to control the medium, change the direction of the medium flow, prevent reflux, cut off the medium and block the pipe. To go against all odds, the valve suppliers are focusing on new technologies to bring more efficient equipment that ensures better performance.

Residential Home Piping Systems

Many kinds of valves are used in residential piping systems with each kind serving a different purpose and specific application. To regulate the water flow in bathtubs, showers, sinks, water heaters, and outdoor faucets, using the right type of valve is essential. For instance, pressure-balancing valves with a single control system are commonly found in bathrooms. Turning the tap right or left will change the water temperature with consistent pressure.

For showers are tubs, thermostatic valves are used along with the pressure-balancing valves to provide greater control of the water temperature. And, the valves found under the sink are stop valves that completely block the water flow. Also, behind toilets and other plumbing fixtures, stop valves are preferred over others.

In the main water plumbing systems, gate valves are used to manage the water flow with an internal gate. More often, gate valves are used as shutoff valves for main water supply lines.

After the main supply enters the residential building, it leads to the water heater that is behind bringing water to the fixtures throughout the building. Faucets and valves manage the water supplies to fixtures and appliances including dishwashers, and water softeners.

Commercial Buildings

In commercial buildings, valves serve a variety of purposes. To carry out the wastewater, hot water, and fire protection, quality piping systems are installed throughout the building. More commonly in commercial complexes, gate valves made up of different materials like stainless steel, and cast iron are used. Also, the reliability offered by the butterfly valves makes them suitable to use in commercial or industrial applications. These can be installed or removed without relocating the pipe systems.

To choose valves for commercial or industrial applications, do consider their durability. There are certain design varieties available in the market, allowing you to choose the material best suited for the preferred building material.

Final Words!

To conclude, the valve manufacturing industry has become one of the critical sectors in the mechanical industry. The design and structure of different valves have made them widely applicable in many industries. Moreover, they require low maintenance, are rust-free, and are highly active to pressure and temperature variations across line fluid.

The no requirement for an external power source or any exterior action makes them highly functional, versatile, and long-lasting. However, industries today need quality, reliability, and innovation when it comes to choosing valves for their purposes. The operational effectiveness and the production ability of the industrial processes rely, in certain ways, on the valve’s functionality. In complex conditions like oil and gas extraction processes, the quality and reliability of a valve is something that can bring a huge difference to the process.

To learn more about the industrial valves, visit EG Valves.

[…] the best 12 manufacturers that you will be able to find on the internet. All of them can produce top-quality valves and deliver them all over the world. It does not matter in which industry you need them, or what […]