Basics: Gate Valves Vs Globe Valves

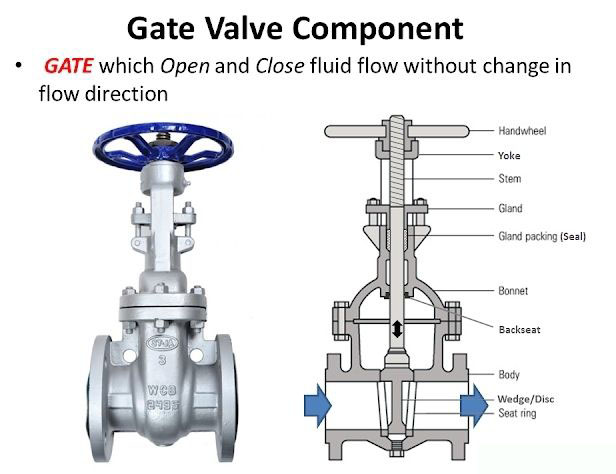

Two of the most commonly used industrial valves are gate valves and globe valves. While some of the functions of both valves may seem similar, they aren’t the same in structure or working principles. For starters, gate valves were invented in the 1840s while globe valves were during the 1850s. Let’s find out what exactly these valves are before moving on to their major differences without wasting any time! Typically featured in industries such as slurry, irrigation, mining, pharmaceuticals, power plants, oil, and gas, gate valves can connect and segregate media. Gate valves are thus named for the gate within the valve that slides on the valve seats to allow the flow of media.

The gates are usually parallel and typically shaped into a knife or wedge. The stem of the valve indicates whether the valve is fully open or closed.

Gate valves don’t leak in most cases although pressure-drop issues can prop. It’s a linear valve that’s popular for securely segregating the flow of media. It’s efficient where tight sealing is a must regardless of what the consistency of the media is.

This type of valve isn’t used for regulating media as it might break down from the process. The lifespan of gate valves is extended by keeping them fully closed or open when in/out of use.

Typically featured in industries such as slurry, irrigation, mining, pharmaceuticals, power plants, oil, and gas, gate valves can connect and segregate media. Gate valves are thus named for the gate within the valve that slides on the valve seats to allow the flow of media.

The gates are usually parallel and typically shaped into a knife or wedge. The stem of the valve indicates whether the valve is fully open or closed.

Gate valves don’t leak in most cases although pressure-drop issues can prop. It’s a linear valve that’s popular for securely segregating the flow of media. It’s efficient where tight sealing is a must regardless of what the consistency of the media is.

This type of valve isn’t used for regulating media as it might break down from the process. The lifespan of gate valves is extended by keeping them fully closed or open when in/out of use. What are Globe Valves?

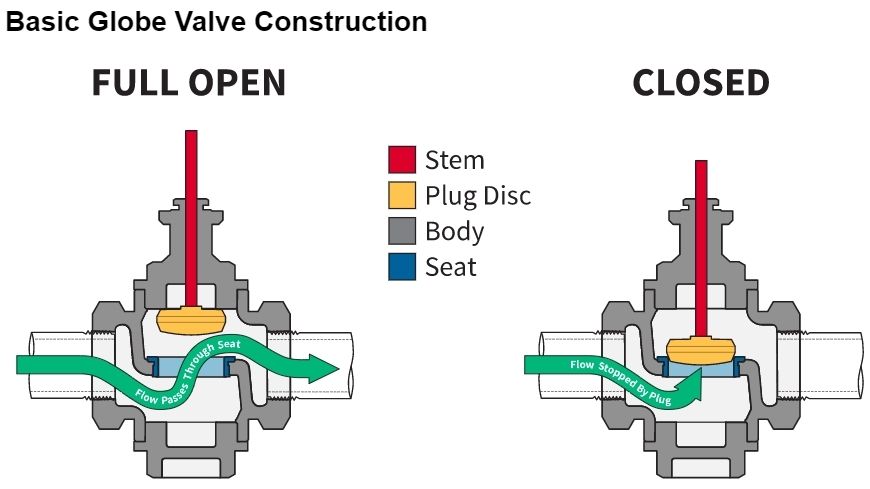

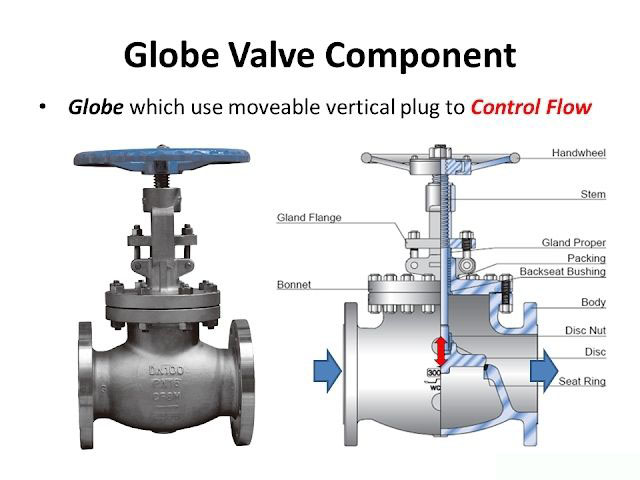

Another linear-motion valve, globe valves can start, stop, and throttle the flow of media that runs through it.

Like gate valves, globe valves also ensure a tight seal with little or no leakage. It’s named after the cone-like plug that goes up and down to control the flow of media but today there are all types of globe valves that contradict this naming. The flow in such a valve depends mainly on the distance between the valve seat and the plug.

The seat erosion is the least in this type of valve while it functions although it suffers a high-pressure drop. Such a valve can even push the flow to alter its flow within the valve body.

Globe valves are generally used in places where leaking is strictly prohibited. It’s the best valve for industries where seat leakage leads to adverse results. That’s why globe valve usually feature as control valves for viscous and corrosive media.

Another linear-motion valve, globe valves can start, stop, and throttle the flow of media that runs through it.

Like gate valves, globe valves also ensure a tight seal with little or no leakage. It’s named after the cone-like plug that goes up and down to control the flow of media but today there are all types of globe valves that contradict this naming. The flow in such a valve depends mainly on the distance between the valve seat and the plug.

The seat erosion is the least in this type of valve while it functions although it suffers a high-pressure drop. Such a valve can even push the flow to alter its flow within the valve body.

Globe valves are generally used in places where leaking is strictly prohibited. It’s the best valve for industries where seat leakage leads to adverse results. That’s why globe valve usually feature as control valves for viscous and corrosive media. The Ultimate Showdown: Gate Valve VS Globe Valve

From internal components to design, installation, functioning, and even cost, there are many differences between gate and globe valves. If you’re torn between the two, all you need to do is comprehend the differences between the two so that you can understand which is most compatible with your needs.

In Gate Valve VS Globe Valve below, we are going to target every trait so that you can pick the perfect one for your business. Let’s dive in!

1. Throttling

Amongst the two linear motion valves, both can start or stop the flow of media, but only one can throttle it. While gate and globe valves look similar externally, the globe valve has extra features.

Gate valves are strictly used for open and shut-off functions because controlling the flow can lead to undue vibrations and noise from the valve and subsequent damage to the seat and disc of the valve. It’s not designed to bear a partial flow of media. That being said, isolation of media is better done by a gate valve than a globe valve.

On the contrary, globe valves are flawless at throttling but it’s not generally used for starting or stopping the flow unless gate valves aren’t available.

The only instance gate valve can throttle is if the valve is 90% closed but it can damage the disc eventually. A handwheel is used manually in globe valves industries for throttling. The seat and disc erosion in such a valve are negligible too.

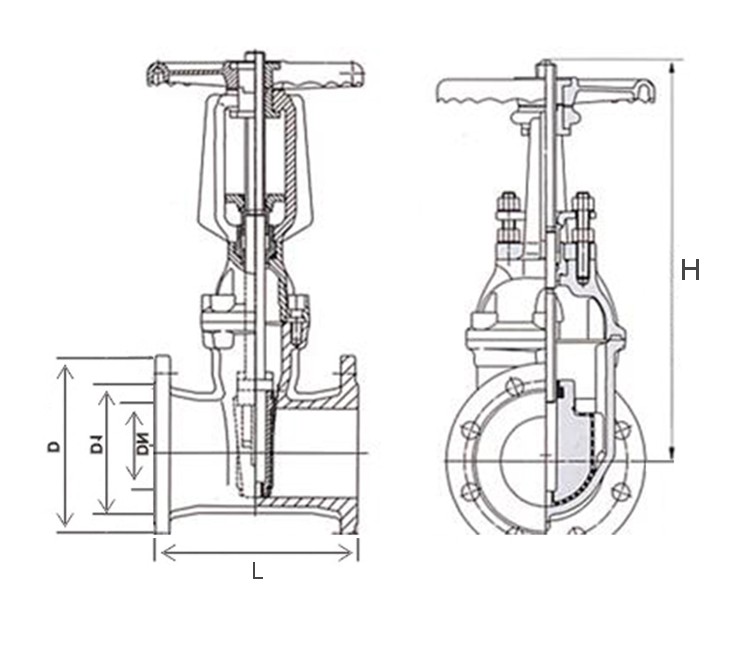

2. Fundamental Built/Structure

Gate valves have a complex design when it comes to their shape. It’s higher than shut-off valves of the same circumference. In this type of valve, the internal area becomes hollow when the media flows as the core components are usually located on the top area.

On the flip side, globe valves have a rising stem and look different from gate valves. Most of the crucial parts of globe valves are situated within the cavity itself. As it’s mostly used for throttling, such a design facilitates changing the flow direction, pressure drop rates, and so on.

Since its primary purpose is to throttle and provide positive shut-off, the design allows obstructions that aid the globe valve in this purpose. The design also permits changes in flow direction and rate that contribute to a high-pressure drop.

3. Design

The design of both gate and globe valves is also drastically different. The main difference is in the form of the inner elements and the form of the flow inside the valves.

In addition, the gate valve may have a rising or nonrising stem while the globe valve is typically a rising stem design. The wedge-shaped gate is helpful to detect whether the valve is fully open or closed.

The stem of the globe valve can be raised or lowered to shut off or turn on the flow of media while gate valves use a handwheel that needs to rotate for the same results. But in the case of gate valves, the handwheel gives no indication of whether the valve is open or closed.

As gate valves are made to fully open or close there isn’t any friction or obstruction to the flow of media during either of the functions. With globe valves, the stem moves up and down to control the flow of media with a movable plug.

4. Height

As the gate structure in the gate valve follows an up-and-down motion when in use, it uses a rising or non-rising stem to process the work.

5. Flow Direction

You can use a gate valve for regulating the flow in both directions although the flow direction of globe valves is limited and indicated on the valve itself. It can shut off the flow in either direction and hence are great under high temperatures and pressures. Turning the handle counter-clockwise opens a gate valve.

For a globe valve, the flow direction arrow is present on the casting or the body of the valve. Reverse flow through a globe valve damages the valve seat badly. Bear in mind that the flow direction is based on the specific type of globe valve.

Gate valves are preferred for low-pressure applications because it’s multi-directional linear motion valve. On the contrary, globe valves are great in situations with high-pressure drops because it’s a unidirectional type of valve.

6. Pressure Drop

You already know both gate and globe valves vary by design. But do you know this is the main reason for its pressure-drop variances?

For instance, gate valves don’t provide any resistance to the flow of media within it while the valve is in an open position. If you record the pressure drop, you’ll notice it’s low across the valve too.

Gate valves are used when the flow of media is straight without any restriction but globe valves force the flow to change direction. Hence, you shouldn’t use globe valves where pressure drop and resistance to the media is not viable.

However, globe valves experience high-pressure drops in the fully-open mode with a sizeable resistance to the flow of media within it.

Owing to their design, you can expect little to no fluid trapping in gate valves while it’s high in globe valves due to its flow direction variations. Gate valves can be used to change the flow of media in several directions but you can’t do the same with globe valves.

7. Difference In Working Principles of Gate Valve and Globe Valve

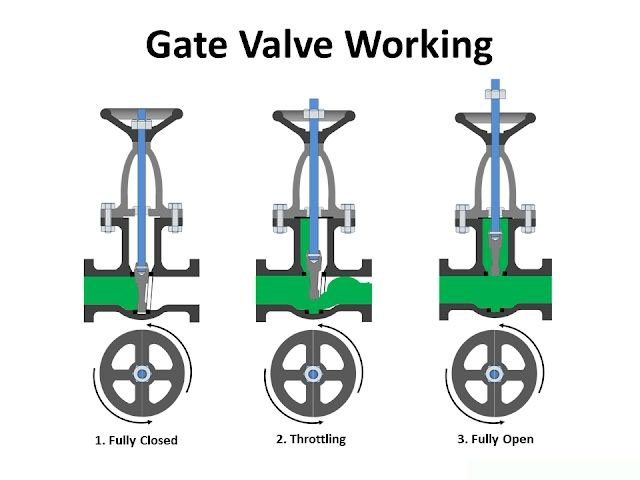

The gate valve uses a gate while a globe valve makes use of a movable plug to move the flow through it. Scroll to know more about how they differ in the way they work.Gate Valve Working Mechanism

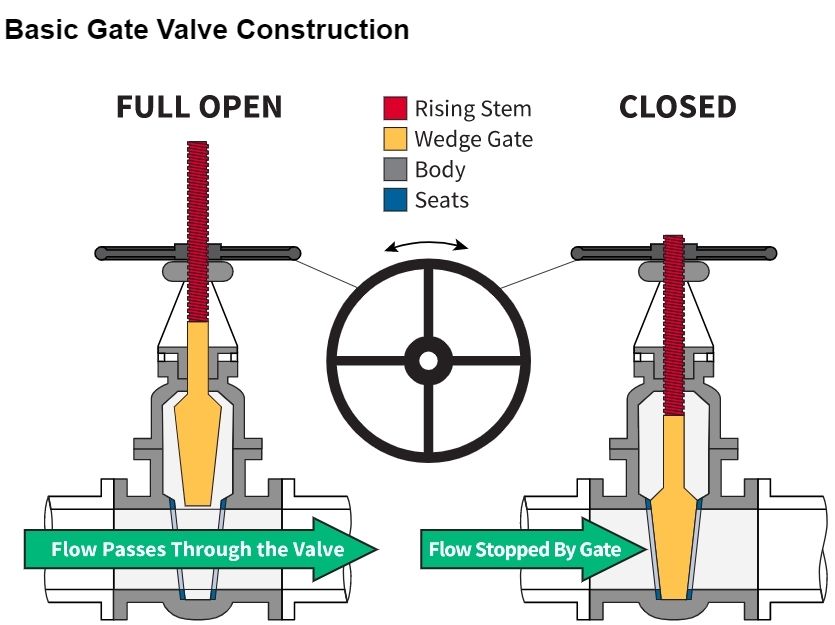

Gate valves put the valve into motion by lodging its disc between the valve seats. The perpendicular movement of the disc to the flow of media either opens the valve fully or closes it. A rectangular gate is placed or moved off the path of the media to regulate its flow.

The working principle behind gate valves is that the steam and gate of the valve move at a downward angle when the handle of the gate valve is turned clockwise. In the anti-clockwise motion, the steam and gate push at an upward angle.

The primary function of a gate valve is to move the media forward using the gate without any resistance or friction loss. Opening the gate partially can erode the disc when the media flows through it.

Gate valves put the valve into motion by lodging its disc between the valve seats. The perpendicular movement of the disc to the flow of media either opens the valve fully or closes it. A rectangular gate is placed or moved off the path of the media to regulate its flow.

The working principle behind gate valves is that the steam and gate of the valve move at a downward angle when the handle of the gate valve is turned clockwise. In the anti-clockwise motion, the steam and gate push at an upward angle.

The primary function of a gate valve is to move the media forward using the gate without any resistance or friction loss. Opening the gate partially can erode the disc when the media flows through it.

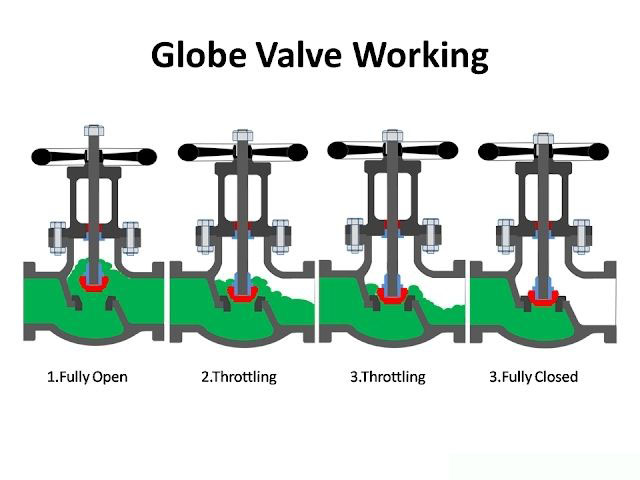

Globe Valve Working Mechanism

Unlike gate valves, the disc inside a globe valve moves parallel to the flow of media. The fundamental principle is focused on the rising stem that allows the flow of media through it.

Globe valves are constructed to start, stop, or throttle the flow of media using a movable plug or disc inside a spherical housing. The valve opens and shuts when the handle is turned using an actuator or manual motions when the disc comes at a lower level using the stem. The flow of media stops when the disc is completely lowered and fully open when the disc is raised to the maximum.

When the handle wheel is rotated clockwise, steam and the valve plug move downward across the fluid flow line, and the valve plug tightly seals between the two valve seats. As a result, once the valve is completely closed, there will be no leakage of fluid whatsoever.

If you turn the handle wheel anticlockwise, steam and the valve plug move upward across the fluid flow line, and the valve opens from its closed position, allowing fluid to flow through the globe valve.

Both gate and globe valves have the same lifespan of eight to ten years. While you can troubleshoot and repair a globe valve while keeping it in place but almost all types of gate valves need to be disassembled for appropriate repair and maintenance.

8. Maintenance Hassles

For both the valve, regular inspection is a must. In the case of globe valves, you should check the glands and the installation points of gate valves for damage. You should remove the buildup of grime, dust, and dirt outside and inside both the valves regularly as well as cycle them at least once a month when not using them regularly.

You can remove the gate valve by removing the body, and stem, followed by the gate. Use silicone tapes at the installation sites of gate valves too. Choose a valve that can ensure the least leakage as it’s directly proportional to maintenance troubles.

For both the valve, regular inspection is a must. In the case of globe valves, you should check the glands and the installation points of gate valves for damage. You should remove the buildup of grime, dust, and dirt outside and inside both the valves regularly as well as cycle them at least once a month when not using them regularly.

You can remove the gate valve by removing the body, and stem, followed by the gate. Use silicone tapes at the installation sites of gate valves too. Choose a valve that can ensure the least leakage as it’s directly proportional to maintenance troubles.

9. Opening and Shutting

The opening and closing mechanism of globe and gate valves also differ by a huge degree. Here are all the other notable differences between the two:- Gate valves must be fully opened or fully closed, unlike globe valves.

- The flow resistance of the media in the valve body is zero in the fully open position for a gate valve. Hence, opening and closing of these valves are easy and less exhausting than globe valves.

- Globe valves have prespecified inlets and outlet directions for the flow of media, which is absent in gate valves.

- The closing-opening mechanism of a gate valve is processed using a disc or plate that moves parallel to the valve seat whereas a globe valve has a plug or popper that moves at right angles to the valve seat.

- You can open a globe valve even at a high DP (differential pressure) while a gate valve will end up in a bind in such a situation and when you attempt to open it, the valve seat will score and end up causing leakage.

- The gate valve has extreme parabolic traits that can’t be used for throttling while a globe valve has the near-linear trait of CV vs % open.

Based on the working principle of gate and globe valves that we learned above, you know full-well that the gate valve isn’t made for controlling the flow.

Instead, gate valves do an above-average job of isolating media and tightly sealing it off. The main function of a gate valve is the segregation of media and if it tries to partially allow the flow of media, the valve will not bear through.

On the flip side, globe valves are good for shut-off and regulation of the media. While the fluid resistance in the globe valve is huge and the open-shut actions exhaustive, the opening and closing duration is minute. This is because the valve plate and sealing point have a good distance between them.

When it comes to the performance of gate valves vs globe valves, each comes with its own set of pros and cons.

Gate valves can close and shut the flow off media while globe valves can do that and much more. Globe valves are often used in the regulation of the media that gate valves are incapable of doing. But gate valves ensure a tight sealing like no other.

Hence, the performance of these two valves can be compared on the basis of a goal or purpose you have. Talk with our customer representatives to discuss which is a good fit for your industrial application.

11. Torque

Based on the working principle of gate and globe valves that we learned above, you know full-well that the gate valve isn’t made for controlling the flow.

Instead, gate valves do an above-average job of isolating media and tightly sealing it off. The main function of a gate valve is the segregation of media and if it tries to partially allow the flow of media, the valve will not bear through.

On the flip side, globe valves are good for shut-off and regulation of the media. While the fluid resistance in the globe valve is huge and the open-shut actions exhaustive, the opening and closing duration is minute. This is because the valve plate and sealing point have a good distance between them.

When it comes to the performance of gate valves vs globe valves, each comes with its own set of pros and cons.

Gate valves can close and shut the flow off media while globe valves can do that and much more. Globe valves are often used in the regulation of the media that gate valves are incapable of doing. But gate valves ensure a tight sealing like no other.

Hence, the performance of these two valves can be compared on the basis of a goal or purpose you have. Talk with our customer representatives to discuss which is a good fit for your industrial application.

11. Torque

The frictional function that exists between the metal parts of a valve and its sealing components creates torque in a valve or the force required to move the valve on its axis.

In a nutshell, globe valves demand higher torque than gate valves. That’s why you’ll often see globe valves with actuators or automatic motor-operated mechanisms to work it. That being said, there are torque reducer gate valves in the market that a single person can activate without any balance stem.

12. Sealing Ability

To know how good gate valves and globe valves seal the media, you need to assess the sealing surface of both valves first.

Globe valves have a trapezoid-shaped sealing surface along the side of the valve core. When you detach the core, it fits with the valve closing. On the flip side, the valve core seals the gate valve and hence it’s more effective than a globe valve.

Gate valves also come with superb shutoff capabilities that makes it excellent to pair with globe valve for upstream flow of media. Upon opening and closing a gate valve, the seat and sealing surface rub and cause friction, leading to serious wear and tear. That’s globe valves usually last longer than gate valves.

When opening and closing, the valve core and the valve seat sealing surface are always in contact and rub against each other, so the sealing surface is easy to wear. When the gate valve is close to closing, the pressure difference between the front and rear of the pipeline is large, which makes the sealing surface wear more serious.

13. Cost: Gate Valves Vs Globe Valves

Depending on the type of gate or globe valve you go with, the difference may be unlike what we can predict.

But on a general note, gate valves are very much cheaper than the same size and material of globe valves. That’s mostly because globe valves have more components than a gate valve such as an actuator or a poppet.

In addition, the extra expense might just be the safety or the reassurance you’re looking for when working with sensitive industrial applications.

The frictional function that exists between the metal parts of a valve and its sealing components creates torque in a valve or the force required to move the valve on its axis.

In a nutshell, globe valves demand higher torque than gate valves. That’s why you’ll often see globe valves with actuators or automatic motor-operated mechanisms to work it. That being said, there are torque reducer gate valves in the market that a single person can activate without any balance stem.

12. Sealing Ability

To know how good gate valves and globe valves seal the media, you need to assess the sealing surface of both valves first.

Globe valves have a trapezoid-shaped sealing surface along the side of the valve core. When you detach the core, it fits with the valve closing. On the flip side, the valve core seals the gate valve and hence it’s more effective than a globe valve.

Gate valves also come with superb shutoff capabilities that makes it excellent to pair with globe valve for upstream flow of media. Upon opening and closing a gate valve, the seat and sealing surface rub and cause friction, leading to serious wear and tear. That’s globe valves usually last longer than gate valves.

When opening and closing, the valve core and the valve seat sealing surface are always in contact and rub against each other, so the sealing surface is easy to wear. When the gate valve is close to closing, the pressure difference between the front and rear of the pipeline is large, which makes the sealing surface wear more serious.

13. Cost: Gate Valves Vs Globe Valves

Depending on the type of gate or globe valve you go with, the difference may be unlike what we can predict.

But on a general note, gate valves are very much cheaper than the same size and material of globe valves. That’s mostly because globe valves have more components than a gate valve such as an actuator or a poppet.

In addition, the extra expense might just be the safety or the reassurance you’re looking for when working with sensitive industrial applications.