The advantages brought by the china valve manufacturers are greater which has improved the industrial valve processing. The technology used in the valve manufacturing process is far different than those of the other processes in the industry.

The applications for these mechanical devices are gaining huge popularity in controlling the pressure and liquid flow in hydraulic systems. The wide uses in different industries have made China valves a crucial part of the piping system. You can select the right valve from the many different types available from the valve manufacturers. The valves come with a different set of features, capacities, and applications.

Also, the functional mechanics of these units vary, and can be manual, pneumatic, or electric. In accordance with your industry application and other specifications, you can make the right choice.

The Steps to Choosing the Right China Valve:

- Before you step ahead in the market or approach valve manufacturers, do consider the intended purpose to invest in the valve. Also, give serious consideration to the kind of material and media you will need to regulate which can either be gas or liquid.

- Find out the exact purpose to use the valve. Do you need it for regulating the fluid flow or to stop the flow? Determine how would you need to operate the unit, either manually or automatically? In many industries, there is a possibility to operate the entire system remotely. Apart from these aspects, do not forget to look after the technical characteristics of installation like the pressure and flow of the liquid or gas.

- Considering the specific requirements, the manufacturing of the valve differs. Right from sourcing to production, the china valve manufacturing process is sophisticated because of the varying composition and materials used. Taking into consideration the operating environment, chemical compatibility, and other requirements, you can easily choose the right valve for your industry.

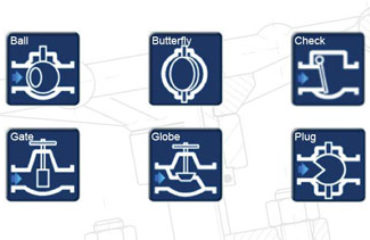

Many different types of valves exist with some of the common being Ball, Check, Diaphragm, Pinch, Gate, Globe, Ball, Butterfly, and Needle valve. These all fall into the category of basic valves but are widely used in big industries including Oil & Gas, Mining, Water & sewage industries.

Ball Valve

The valve passes and stops flow by the quarter-turn rotational motion of the hollowed-out ball-shaped disk, which is fitted inside the pipe.

Applications

There are many designs available in ball valves to meet specific industry requirements. Featuring pressure relief, variable flow control, flow splitting, and mixing, the ball valves are used in both gaseous and liquid applications that need air-tight service. Being less expensive than other valve types, these valves find their best usage in the clean and slurry applications along with reliably serving the high-temperature and high-pressure applications.

Plug Valves

These valves bring in use a cylindrical or tapered plug to start, stop or throttle flow.

Applications

For tight shut on/off applications, plug valves better suit the oil piping systems, chemical servicing, high-pressure and temperature flow systems, and the corrosive substances processing.

Butterfly Valves

The working mechanism is the same as the ball valve; the only difference is replacing the ball-shaped unit with a thin disk.

Applications

Being lightweight and compact, butterfly valves are ideal to be used for managing large fluid flows of fluid. For instance, in the water treatment plants or the water distribution systems, these valves perfectly meet up the specific application areas. Using gears, automatic actuators, gears, handles, and butterfly valves are suitable to be used in food processing, power generation, lubrication system, steam services, and sanitary valve applications.

Gate Valves

Widely used in the taps, these sluice valves make the passageway either fully closed or open with no in-between position. Also known as the multi-turn valve, the gate valve’s functionality is controlled by the threaded stem.

Applications

Commonly in the manufacturing, automotive, pharmaceuticals, and marine industries, gate valves are extensively used with taking up limited space. For the wastewater and fire protection applications, gate valves with rising stems are used for underground as well as the above-ground applications.

Globe Valve

The Globe valve works similar to the gate valve with the varying factor being the use of disk at the place of a wedge.

Applications

Globe valves are widely used in cooling water systems and fuel oil systems to regulate the flow while ensuring the leak tightness. In the chemical feed, feedwater, and condenser air extraction systems, globe valves are popular due to their shutoff capability and good throttling capability.

For low-temperature applications, globe valves contribute to simple operation and to protect the packing system. However, for high-temperature steam service, these valves are used to keep the pressure above the disk else there will be a contraction in the stem and that may tend to lift the disk off the seat.

Pinch Valve

These valves have a pinching mechanism and a molded rubber or synthetic material sleeve to throttle flow. Its simple design leads to minimizing downtime and low maintenance costs.

Applications

Pinch valves are known for their excellent resistance to chemical agents and also for their capability to perform best in adversative weather conditions. For fibrous and corrosive applications, these valves are finding their greater use. This is because of their ability to easily block or close. Manu industrial processing plants are using the pinch valves in order to improve the production facilities and operative costs in applications including the hot steam and abrasive slurries.

Check Valves

Check valve passes the fluid in one direction only with the two ports. Since they work unidirectional, check valves are also known as one-way valves or non-return valves that are used to prevent backflow in the system.

Applications

The performance capabilities of the check valves lead to effective operations for varying pressures. These valves are known for their versatility and are widely used in all kinds of applications that work under particular operating temperatures. Not only the valves are capable of processing complex material types, but also regulate flow in extreme variations of temperatures.

Though types of valves are quite common in the industry, it takes complete dedication and effort to choose the right valve for your needs. Before you move ahead with making the final choice, below are a few simple tips to help you choose the right valve for your application:

In order to meet your industrial-specific requirement, you must consider the series of the valves in terms of size. There are large-sized ones, small ones, and the new type ones. Now the question arises about how to find out the dimensions of the valve.

Well, to calculate the dimensions, look at the parameters associated with the circuit operation. One prime aspect is the pressure changes which is why you should get the appropriate valve size. Also, operating temperature is a crucial aspect that makes you choose the right valve. This temperature indicates the valve body, ambient, and circulating temperature. For a good decision, choose the valve type that bears the highest temperature without any failure.

From adjusting flow to backflow prevention to shut-off flow, take into consideration the temperature and pressure variations so as to find the best valve that meets your industry requirements. In addition, also determine the flow velocity and flow rate of the liquid which can make you avoid picking the wrong size.

Material of construction

Another essential consideration is the material of the valve. Typically, the choice should be made considering the support needed by liquid or gas to pass through the system. Often, the valves made up of plastic seem to resist corrosive or harsh chemicals in comparison to those made up of metal. The valve material is expected to satisfy all the requirements in terms of appearance, size, mechanical property, and corrosion resistance. For instance, carbon steel with high corrosion resistance or hardness offers poor performance, whereas sealing necessities are essential to achieve. Using metal-based valves affect many industries like underground pipelines, water treatment, sewage handling, aviation, chemical processing, nuclear power generation, and more.

This effect of corrosion has made industries work with alternative options such as PVC valves as they are virtually unpretentious by corrosive parts. Also, PVC valves hinder any organic growth, making them ideal for ultra-pure applications.

This is why the material selection should be made wisely so as to avoid any further issues.Over the last few years, Polyvinyl Chloride (PVC) valves are dominating both the residential and commercial sectors. Because these valves comprise appropriate additives that provide the desired physical and chemical compatibility.

Performance Requirements

Apart from the material consideration, the performance of the valve depends on the pressure and temperature. The need is to determine the pressure and temperature variations in order to select the location of the valve. Often, the metallic valve tends to bear higher temperature and pressure in comparison to other materials like plastic.

Considering the seal performance, the ability to prevent leakage is another aspect. It is significant; else the leakage would lead to failure of equipment and may lead to some industrial accidents. There are some prime aspects that need much consideration, such as the opening/closing device attachment and two seal surfaces, the space between the valve stem and stuffing, and the joint between the cover and body of the valve. These aspects directly impact the cutting of the medium ability and also a few consequences.

Specific Requirements

No matter what, the selected valve must perform the desired function. Before reaching out to another step, you must take into consideration the cracking pressure and needed response time to open the valve. Furthermore, you also need to look after whether the valve closes or opens in normal conditions.

For some specific design structures, the valve opens up with a positive downstream and that is popular as closed check valves. However, there are some other designs as well that work on backpressure. It is significant to consider the adjustment of the industrial construction to make the right choice.

Some kinds of valves are meant to fix in the vertical position, however, others in a horizontal way. Here, the direction of the flow and the flow density is essential for these valves to fix vertically. Looking after all these aspects means getting a more reliable product.

Maintenance of the Valve

To ensure the adequate performance of the valve in the piping system, it is crucial to check and maintain the valve at regular intervals. To make the valve perform in normal conditions, it is important to examine the valve after its installation. To begin with the inspection process, you need to check whether the seal face or valve stem is abraded. Moreover, the effectiveness of the seal should also be checked for adequate functionality. The other important parts are the flange and holders that help keep the valve functioning well.

The functionality of the valve depends on the working condition and that should be kept stable. More specifically in the harsh conditions, the valves should be protected by means of different measures.

Before making any final choice, you need to consider the maintenance factor. This is quite crucial if you want to ensure the stability and reliability of the valve. For instance, the ball valve besides adequately controlling the liquid or gas flow may lead to the best working of the unit.

The valve connection type directly affects the need for repair or replacement. Remember, each kind of valve connection comes with its own set of advantages and disadvantages.

Final Words!

China Valves are popular and widely used equipment in different fields like chemical, metallurgy, electric power, petroleum, urban construction, environmental protection, etc. The advances in technology and the gradually expanding industrial need have led the valve into a promising future.

China is booming as the biggest provider as a consequence of the industrial structure. With the upcoming opportunities, combined with the greater challenges, the China valve industry is preceding its pace into a lively prospect.

Getting all the needed information ahead of time, it will become easy for you to choose the right valve for any specific application. By starting with the fundamental valve requirement, you can make the selection much more at ease.

For quality industrial valves, visit EG Valves to choose the best valve. The many types and configurations available with us will make it convenient to choose the right valve as per your requirements.