For a butterfly valve with a metal seat, both sealing surfaces of the china valve are metal material or other hard material. They do have not such a good sealing performance but have good mechanical properties, such as being high temperature resistant and anti-wear. While, for a resilient seated butterfly valve, one sealing surface is made of metal material and the other sealing surface is made of non-metal resilient material. The resilient seat has good sealing performance, but poor mechanical properties, such as not being high temperature resistant and easy to wear.

The butterfly valve has good sealing performance and can reach zero leakage, but it has poor thermal adaptability and serves a short life. The hard seated butterfly valve has not had good sealing performance and can’t reach zero leakage. Though some manufacturers declare that their products can do. Metal seated butterfly valve can be used in part corrosive medium, but Resilient seated butterfly valve can’t. The two different seats can complement each other in different working conditions.

Generally speaking, there are the following differences between the butterfly valves of two different seats.

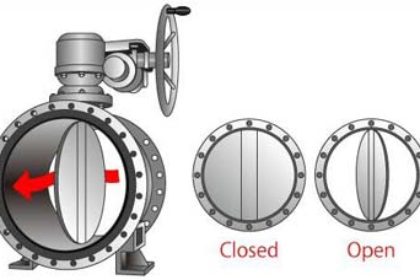

1 Different Structure

The butterfly valve with resilient seats is of the central line design and the Metal seated butterfly valve is of a single, double or triple eccentric design.

2 Different suitable temperature

A resilient seated butterfly valve is used in average temperatures. While a Metal seated butterfly valve is used in low, normal, and high temperatures.

3 Different pressure

It is used in low and normal pressure. A Metal seated butterfly valve can also be used in middle-high pressure.

4 Different sealing performance

It is a metal seated butterfly valve that has comparatively good sealing performance. The latter can seal well in high pressure and temperature.