Whether for your next construction project or any hardware dealing, you might need valves for the purpose. To meet up with the reliable and most authentic pipe valve manufacturers, there is no one better than the China valve industry.

The industry of valves in China is leading the world. In recent years, due to the big investment opportunities and the policy modifications regarding infrastructure development, the valve industry has gained the topmost position for quick development.

The widely used machinery and equipment in industrial processes generally include pumps, compressors, fans, drying/isolating equipment, and valves. Despite each technology and equipment fulfilling specific requirements, industrial valves are quite popular to be used in some fields including chemical, petroleum, metallurgy, urban construction, petroleum, and many more. To ensure the smooth running of any industrial unit and system, industrial valves have a big role. Recent research reveals the industrial valve market to reach up to 85.19 million by 2023. In fact, the market value of the global industrial valves market is $62,412.1 million in 2021

Depending on the end-user industry, the oil and power industry leads in 2020 accounting for the highest revenue of 36% of the market.

Valves, the mechanical devices that are commonly found in pipeline systems, help to regulate the flow of liquid through the pipes. Usually, found on the wider part of the pipes, the valves are affixed to the pipelines.

Due to increasing opportunities, and ongoing demand, the valve industry is gradually expanding and being led by China. Indeed, the world of products and valves made in China has been steadily expanding over the years. This is because the industrial and manufacturing sectors in China are able to process quality products at affordable prices. This way, the country emerges as a strong competitor against other developing economies. In comparison with the developed countries, China is leading in terms of low cost, labor force, and necessary government support.

The Labor Factor

While it is possible to find skilled workers in other countries as well, China still leads because of the existence of an adequate system of industries and development systems.

Many other countries usually lack resources and do not afford to maintain a required industrial system. China leads in regards to access to the latest technology and manpower due to its massive population and developed technological sectors. Currently, China is the world’s most populous country with a population of around 140.21 crores, according to the 2020 census. This high population of the country plays a big role in helping the country with affordable labor in addition to having an advanced industrial system.

The Quantity

Made in China products are supplied to different countries and in huge quantities. This is one such aspect of the country’s affordable merchandise. The number of products that are being transported, allow the country to keep the prices low while at the same enjoying bigger profits.

Unique Opportunities

In today’s highly competitive global economy, working with Chinese manufacturing companies provide businesses with many unique opportunities. For businesses who want to maximize their savings and efficiency, the valve industry can make it possible in China. Not only do they provide a quality platform to connect with, but also allow businesses to sift through and research any company thoroughly before making any contact.

No matter whether you are an individual or any multinational corporation, the china industry can help you meet your industrial requirements in one fell swoop.

They offer a variety of essential tools that help you research many vital aspects of trade with Chinese companies. This helps make your business operation streamlined and less time-consuming. Additionally, before you make any investment, businesses can have comprehensive trade consultation and an abundance of necessary trade tools needed to help your business maximize the varied opportunities available.

Certification

The standard certification reflects the quality of the product. In fact, this is a quality measurement tool that rest assured that the product will meet essential quality standards. Besides this, it reflects that China’s valve manufacturers are responsible for product quality, which leads them to come up with high-quality and quite efficient services.

The reputation of the manufacturers comes up as a vital aspect to take into consideration. This is where the world’s leading valve manufacturing companies and Valve Industry hold and strive their level best to offer the highest quality standards in China. Additionally, legitimate China suppliers offer replacement or upkeep as part of their after-sale service. They have got a professional technician to resolve the issues with their devices.

Industrial Valve Insights

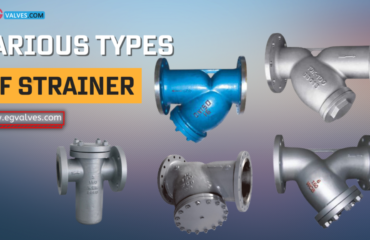

Compared to the previous years, the demand for industrial valves has grown more. Industrial valves are of many kinds, such as globe valve, ball valves, butterfly valves, gate valves, check valves, pressure valves, and Diaphragm valves.

Each and every type varies in accordance with the function performed and their dependency on the different working principles.

Quite effectively, ball valve manufacturers are able to regulate the fluid flow in many demanding industrial applications. The two vital aspects of the ball valve’s flow control spherical element include the port size and the support by the body. Available in three patterns: Full port, regular port, and reduced port. In 2018, China ball valve have accounted for over 25% of the revenue share.

Their tight-shut-off feature makes them highly useful in commercial and industrial piping settings. Adequately designed high-temperature and high-pressure ball valves are easy to find in usage in power, marine, petrochemical, refining, catalytic reforming, and industrial processes.

Such valves are thought to be better than some different kinds of valves. They will be taken into consideration to be simple to apply and may adjust the high pressure, and temperature and go with the flow quantity of the water pumps. Ball valves perform the best in those situations once the fluid flow needs to be closed completely. This example features the valve located on the main line presenting one with water in the location.

In recent years, there is a great demand for gate valves as they are used widely in domestic and commercial buildings. The typical function of the gate valves is to halt or start the fluid flow. Partial fluid flow is not achievable with these valves as either they can be fully open or closed.

This feature helps them completely shut off the fluid flow. Such valves can be found in different materials. The most common is brass and iron valves with less common materials being stainless steel, alloy steel, forged steel, cast iron, and so forth.

Valves with a stable wedge consist of a simple yet sturdy build. It can consequently be used for all types of liquids, which includes hard fluids as well. As it entails simple production, it entails complication and maintenance. This feature makes it useful in most pipe strains. Valves with bendy wedges are other types that have the capability to stand in various climatic conditions. Those valves are very bendy and may be used for lots of functions. The parallel aspect valve is a common bendy wedge valve that is commonly used in many applications.

Going further to the other valve type, check valves are expected to witness exponential growth in the coming years. The industries that use the pipeline for fluid transportation rely on check valves. Such valves are also known as non-return valves because of their unidirectional flow. This feature restricts the reverse flow with the closing/opening of the valve depending on the hydraulic pressure.

Amongst all those check valve manufacturers kinds, the check valve is one of the primary kinds that are used to shut off and prevent backflow. There are numerous kinds of this form of valve such as ball check valves, stop-check valves, cone check valves, disk valves, and so on.

- The ball check valve is more preferred over others. In this type, the ball in the shell of the valve easily fits against the side through which the fluid enters. Spring is used to push the water and pass through the valve. On turning off the supply, the spring pushes the ball and prevents it from flowing backward through the pipe.

- The second type of override prevents drift irrespective of flow direction or pressure. It not only shuts off in response to backflow or excess pressure but additionally may be intentionally shut via an external mechanism, thereby stopping any flow irrespective of high pressure.

- Another one matches the functionality of the check valves; however, the plug that seals the valve appears similar to the cone. It also can be called a lift check valve wherein the disc, occasionally called a lift, may be lifted off its seat via higher pressure of inlet or upstream fluid to permit go with the flow to the opening or downstream aspect. The cone is held on a bar, permitting it to lift out of the way while the water is flowing and drop back into the area whilst the water is off. If water backflows via the pipe, it pushes up towards the cone, developing a seal that keeps it from going any further.

- The fourth one is the disk valve which is also referred to as the swing check valve. It operates in the same manner as ball and cone valves, but the plug that settles over the opening is a disk. Disk and cone valves tend to wear down extra due to the fact they have got extra shifting components and due to the fact they get bumped around on the pinnacle of the waft of water whilst its miles are turned on.

Commonly used in HVAC systems, are chemical feed pumps, condensate lines, and steam lines where the functionality relies on the reverse flow prevention feature. For another wide range of industrial applications within wastewater treatment, water supply, gas supply, petroleum, power generation, and butterfly valve is the highly preferred option.

The butterfly valve is particularly utilized in large pipes and is defined as a disk rotating on a diametrical axis inside a pipe, also used as a throttle valve or a damper. Typically, it is a type of device that controls the drift, used to administer a certain fluid that might go with the flow through a fixed phase of a pipe.

Considering its operation, the butterfly valve’s functionality is similar to the ball valve. With a flat circular plate, the valve is located in the middle of the pipe, and the plate has a rod through it that is connected to the outside of the valve. This valve works by rotating the handle and turning the plate over both in a parallel role, or perpendicular to the fluid flow.

Many other varieties of the valve can be easily found in the average household such as the valves which regulate the gas or valves which can be utilized by washing machines to alter the glide of water going to and from the device.

Due to their simple design structure, valves which include hand-operated valves may be manually managed through the use or turning of a handle or wheel. On the other side, the complex valves are automatic and function via external input. These kinds of valves generally require an actuator. The actuator works by way of stroking the valve depending on the set-up and input. This sort of set-up allows the valve to be located and in flip allows control throughout more than a few necessities.

In Conclusion

China is a hub for foreign investment, due to its wide population and strong industrial set-up. Many popular industries such as Oil & Gas, Agriculture Chemicals, Food Processing, and Pharmaceuticals, are making a new path for China’s industrial valve manufacturing companies. These industries are primary contributors to the Industrial valve market, and it is expected that the requirement for the China Valve Industry will rise as there will be more R&D for such industries.

The Leading China Valve Manufacturers!

EG Valves Manufacturing Co.Ltd is a China-based valve manufacturer specializing in providing high integrity and pressure valves for different industries. Their products cover valves and industrial equipment for the valve that are exploited in several related industries.